Non flammable, BIO 3010 avoids any need to classify the area of use as ATEX (Regulation of July 8th 2003). On workcamps, BIO 3010 replaces fuel which can be at the origin of fire starts. Fuel has a flash point of 55°C in a 160 °C environment.

BIO 3010, does not contain any solvent and does not emit vapour. More over, it is non irritating,

has very little dehydrating effect on skin tissue. This preparation does not contain any substance

listed as being carcinogenic, mutagenic, toxic, reprotoxic, harmful, irritant, sensitising, corrosive

or dangerous for the environment (Regulation of November 9th 2004). BIO 3010 does not cause

any occupational disease. There is no need of a special medical supervision. Never use available

fuel on workcamps and, classified carcinogenic of

class 3.

BIO 3010 immediately satisfies the Regulation of May 29th 2000 related to VOC emissions. It is

rapidly and completely biodegradable. It protects the environment in the event of an accidental

spill and riverside populations. It requires no authorisation or declaration of use to government

authorities (Regulation 2002-680).

BIO 3010 is easily and totally biodegradable according to OECD 302 C test (manometric

monitoring during degradation).

BIO 3010 is classified as N.I.W. (Normal industrial waste). After use, it can be collected free of charge as part of an added-value programme.

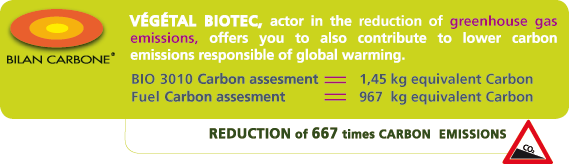

BIO 3010 is formulated from 100% plant origin and renewable constituents, having been the object of an analysis of their life cycle (ISO 14040).

* Assessment calculated for a ton of product made,

packaged in a plastic container

and delivered to

1000 kilometers of its place of manufacturing

| PROPERTIES | |||

| Aspect | |||

| Color * | |||

| Odor | |||

| Density at 25°C | |||

| Freezing point |

*This product is made and based on natural plant oil esters whose origins do not make it possible to specify a constant color. This one can vary according to the places of production and the climatic conditions before harvesting. A difference in color even extremely important does not influence at all product performance.

| PROPERTIES | |||

| Asphalt removing time for BIO 3010 | |||

| Asphalt removing time for Fioul |

| PROPERTIES | |||

| Flash point closed cup | |||

| Auto-ignition point | |||

| Lower explosibility limit | |||

| Upper explosibility limit | |||

| Vapour pressure | |||

| Content of explosive, oxidizing, flammable, easily flammable, extremely flammable substances |

1272/2008 CLP |

| PROPERTIES | |||

| Iodine index | |

||

| Totox (Anisidine index + 2x Peroxyde index) | |

|

|

| Accelerated test of oxydability (Rancimat Test) - Debit - Temperature - Time |

- - - |

20 100 5,8 |

l/h °C H |

| Content of toxic, very toxic,

carcinogenic, mutagenic, reprotoxic, harmful, irritant, or corrosive substances |

1272/2008 CLP |

| PROPERTIES | |||

| Biodegradability | |||

| VOC content | |||

| Solvent content | |||

| Content of substances dangerous for the environment | 1272/2008 CLP |

| Supports involded (equipment or materials) | ||

|---|---|---|

| Workcamps | USE PURE - Spreader ramps and emulsion circuits for finishers with integrated ramps - Edges - Dirty tools (handles and teeth of rakes, shovels, etc.) - Dirty clothing - Dirty gloves - Dirty shoes |

|

| USE PURE - Finisher table - Profiler conveyor flanges - Finisher or profiler hopper - Finisher supply and supply screw - Finisher track - Sump of loader carrying the asphalt - ECF machine sledge - Tools (scrapers, shovels, rakes, etc.) - Manhole covers - Shoes - Vibratory plates - Chaussures - Plaques vibrantes |

||

| Workshop | USE PURE : Can be rinsed in the water with the high-pressure equipment - Metal parts with asphalt - Metal parts with grease - Dirty clothing - Dirty gloves - Dirty shoes |

|

| Factory | USE PURE or DILUTEDIN THE WATER - Skip, shuttle or scraper conveyor for asphalt - Truck body |

|

| - Metal parts with asphalt - Metal parts with grease - Laboratory glassware with emulsion or asphalt - Dirty clothing - Dirty gloves - Dirty shoes - Asphalt filter - Glassware and other laboratory equipment |